Custom Polyurethane Products and Solutions for All Industries

Our in-house team has the capability to design and manufacture bespoke polyurethane products for any application or industry.

At Richmond Wheel & Castor Co we’ve been customising polyurethane moving solutions for over 40 years, with leading design and manufacturing techniques that allow our team to create tailored solutions for your required application.

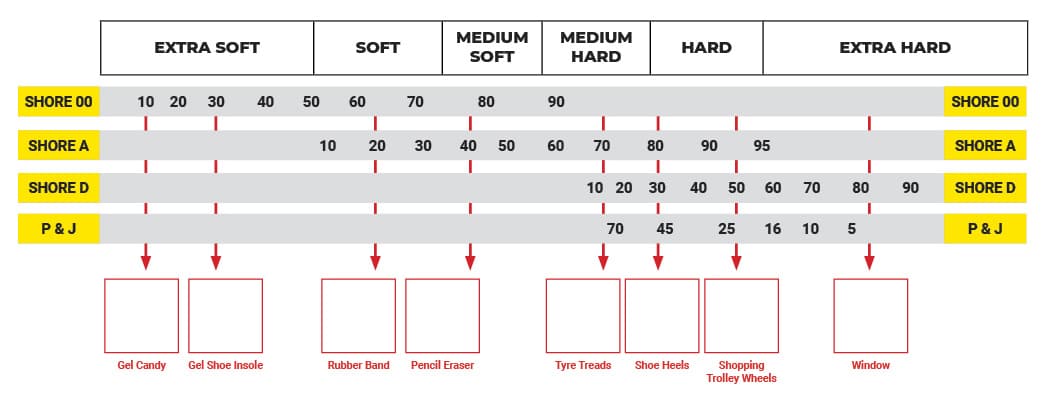

With the highest abrasion resistance of any polymer family, polyurethane is also the most versatile, allowing our team to make products within a broad hardness range – meaning it can be the perfect replacement for almost any rubber, injection moulded plastic or engineering plastic materials.

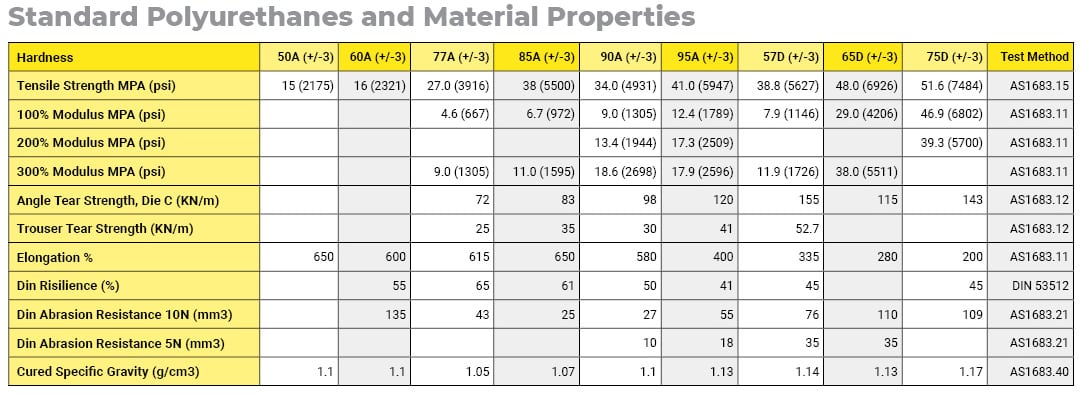

Our standard hardness range can cater for any application, with a wide-range of stock in-house for fast order fulfilment.

This includes 50A, 60A, 77A, 85A, 90A, 95A, 57D, 65D and 75D and standard colour options of Red, Black, Orange, Grey, Yellow and Green.

The perfect partner for custom polyurethane products

For specific applications Richmond Wheel & Castor Co. can expertly manufacture polyurethane products in any hardness from 25A to 85D.

How does polyurethane compare to alternative material selections?

| Compared to rubber | Compared to metal | Compared to injection moulded plastics |

| Superior abrasion resistance | Abrasion resistance | High impact resistance |

| Wide range or hardness for more application flexibility | Non-corrosive | Much lower tooling cost |

| Lighter load bearing | Light weight | Elastic memory |

| Cut and tear resistant | Flexible | Thick and thin section mouldings |

| Uv and ozone resistance | Impact resistant | Noise reduction |

| Lower cost tooling | Nonconductive | Lower and higher temperature range capable |

| Thicker sections possible | Non sparking | Resilience |

| Parts with very thick and thin sections possible | Lower cost fabrication | Elastic memory |

| Colourability | Lower cost tooling compared to cast steel/iron parts | Wide range or hardness for more application flexibility |

| Can be manufactured with a FRAS Rating (fire resistance & antistatic) | Noise reduction in impact applications | Abrasion resistance |

| Won’t damage other steel or concrete surfaces like steel components |

What polyurethane products can we manufacture for your business?

Using precision engineering techniques and the latest equipment, Richmond Wheel & Castor Co can design and deliver any type of polyurethane product for your business needs!

By utilising Richmond’s in-house moulding processes we can manufacture custom shapes, hardness variability and load bearing solutions, giving us a distinct advantage over traditional suppliers across Australia.

With nearly 10,000 products in our growing range, why not talk with our design and engineering team about our custom polyurethane product solutions?