Key Project – Roller Supply for the Regional Rain Link

In July 2013, we were subcontracted by the Baulderstone Leighton Joint Venture to supply adjustable pipe rollers for the positioning and installation of dual 660 mm water main pipes on the underside of Ballan Road and Armstrong Road bridges in Wyndham Vale.

The installation of the water main pipes was a necessary part of the Victorian government’s Regional Rail Link development throughout western Melbourne – a landmark infrastructure project designed to remove major bottlenecks in Victoria’s rail network.

The development involved dedicated regional tracks built from West Werribee Junction to Deer Park, then along the existing rail corridor from Sunshine to Southern Cross Station, including new railway stations. Once completed, passengers on the Geelong, Bendigo and Ballarat lines were able to enjoy a streamlined journey through the metropolitan system.

Scope of Project

Richmond was engaged under Supply Contract WPE-CON -0212 for the manufacture and supply of permanent and temporary bridge connections for the water mains. This included:

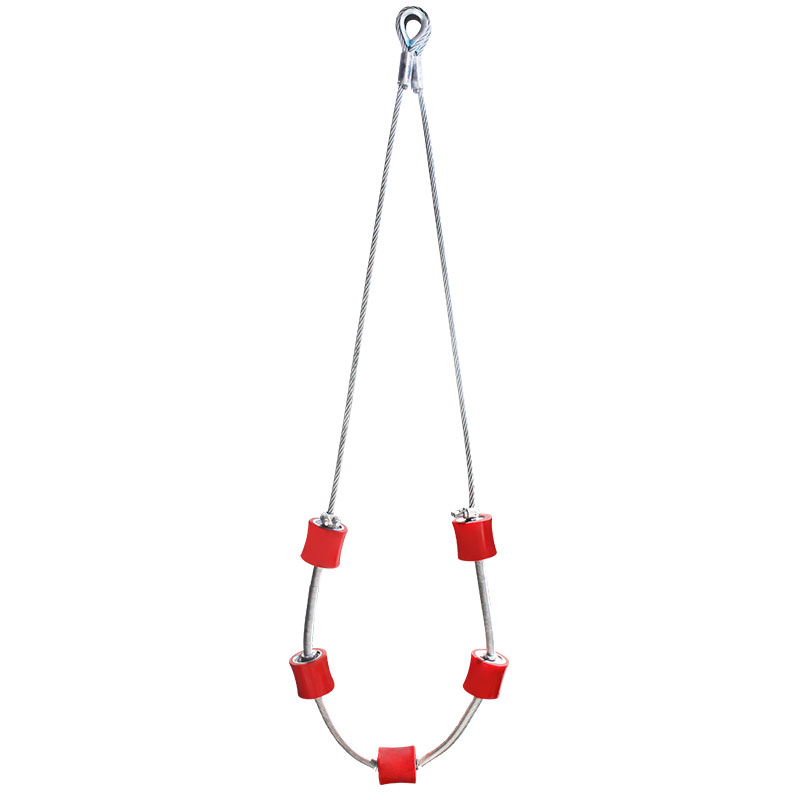

• permanent hanger sets

• temporary roller hanger sets including temporary works design

• temporary bridge pier rollers

• temporary trench rollers for launching the pipes under the bridges.

Design Considerations

Due to physical constraints involved in the construction of the project, pipe hangers could only be placed every 7M. The pipe involved in the project was mild steel cement-lined water pipe, which has a protective Sintakote coating. The rollers supplied by the Richmond team had to be height adjustable to allow for installation of permanent pipe supports. Dynamic loads were also generated during pipe launching.

Launching the Rollers

The rollers we supplied for the water main pipe lengths were P/N 055 LAUNCHROLL rollers. These rollers were used to support the pipeline during welding, as well as to align the water pipe with the temporary pipe slings. The flexibility of the pipe rollers allowed for both the welding and alignment processes to be conducted without dismantling any part of the pipeline, or without compromising the integrity of the pipeline.

Outcome

The Richmond engineering team designed and manufactured pipe sling rollers to successfully launch the water main pipes under the bridges and suspend them in position ready for the permanent brackets to be attached.

We met client milestones to ensure the project finished on time. This also included components that were permanent and had to be cast into the bridge deck slab prior to pipe launching. Rob Keens, Utilities Manager for the Baulderstone Leighton Joint Venture, said ‘Richmond Wheels & Castors was selected for the job because of its novel design solution which included chains, wire ropes and roller systems that were easy to install and adjust and provided a great solution for a difficult engineering task. Richmond supplied good quality workmanship on time which met the needs of the project. All persons onsite during the installation were extremely happy with the system and how easy and quick it was to install the water mains under the bridges.’

Installation

- Armstrong Rd Bridge: 190 m (42 slings, 44 perm hangers)

- Ballan Rd Bridge: 60 m (16 slings, 18 perm hangers)

- Coating remained intact with no gauging or delamination occurring

- Slings easily self-adjusted to account for joints

- Pulling force for 60 m bridge – 200 kg (winch only needed to idle)

- All components were testing to or confirmed to Australian standards

Pipeline Construction Specifications

- Pipe type: Mild steel cement lined

- Pipe coating: Sintakote

- Pipe OD: 660 mm

- Weight: 213 kg/m